Safety data sheets (SDS) are crucial documents that provide essential information about hazardous chemicals and substances used in the workplace. SDS is designed to help ensure the safety of workers and to protect the environment by providing information on the proper handling, storage, and disposal of chemicals.

SDS contains detailed information about the properties of each chemical used in the workplace, including physical, health, and environmental hazards. By providing this information, SDS helps workers understand the potential risks associated with using a particular chemical and take the necessary precautions to ensure their safety.

SDS is a legal requirement in most countries. It is a necessary component of any effective hazard communication program and is required by law to be readily accessible to workers. By ensuring compliance with regulations, SDS helps protect workers from potential fines and legal penalties.

SDS provides information on the proper disposal of chemicals, which helps protect the environment. This information helps prevent pollution and reduces the risk of environmental damage caused by hazardous waste.

In the event of an emergency, such as a spill or release of a hazardous chemical, SDS provides critical information on the proper response measures. This information helps first responders and workers to contain and clean up the spill quickly and safely.

In summary, SDS is an essential document for ensuring workplace safety, compliance with regulations, environmental protection, and emergency response. By providing critical information on hazardous chemicals, SDS helps protect workers, the environment, and the public from potential harm.

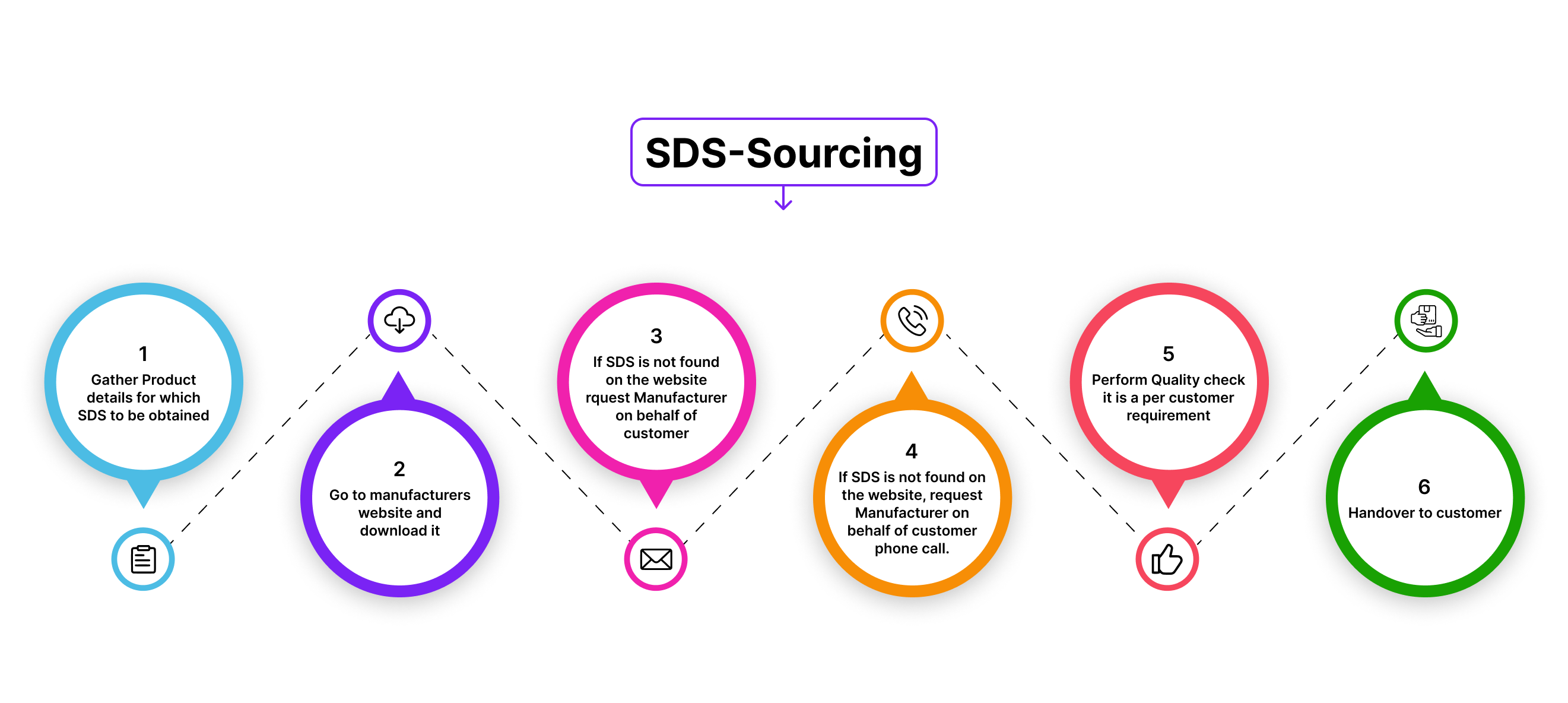

Sourcing refers to the process of finding and obtaining the necessary materials, products, or information required for a particular purpose or project. In the context of Safety Data Sheets (SDS), sourcing involves locating and obtaining the SDS for specific chemical substances or products to ensure safety and regulatory compliance.

The first step in sourcing SDS involves identifying the specific chemicals or substances for which SDS are required. This could include chemicals used in manufacturing processes, industrial applications, or consumer products.

Once the chemicals or substances are identified, the next step is to determine the suppliers or manufacturers of these products. This may involve consulting procurement databases, supplier directories, or industry contacts.

Manufacturer/Suppliers are typically the primary source for obtaining SDS. Contacting them directly via email, phone, or through their website is a common approach. Provide detailed information such as the product name, batch/lot number, and any other relevant details to facilitate the retrieval of the SDS.

Many suppliers and regulatory agencies provide SDS online through their websites or databases. Checking these resources can often yield quick access to the required SDS without the need for direct communication with suppliers.

In some cases, third-party providers specialize in compiling and distributing SDS for a wide range of chemical products. These providers often have extensive databases and can help source SDS efficiently, especially for less common or niche chemicals.

Regulatory agencies such as OSHA (Occupational Safety and Health Administration) or ECHA (European Chemicals Agency) may also provide access to SDS or offer guidance on obtaining them. They play a crucial role in enforcing safety regulations and ensuring compliance with chemical safety standards.

Trade associations or industry groups associated with specific chemicals or industries may have resources or connections to help obtain SDS. They often provide valuable support and information related to safety and regulatory compliance within their respective sectors.

It's essential to maintain detailed records of all communications and transactions related to sourcing SDS. This documentation serves as evidence of compliance and may be required during regulatory inspections or audits.

Upon obtaining SDS, it's crucial to review them thoroughly to ensure they contain all necessary information for safe handling, storage, and disposal of the chemical products. Compliance with regulatory requirements should be verified to mitigate risks effectively.

SDS should be periodically reviewed and updated to reflect any changes in regulations, product formulations, or safety information. Staying informed about revisions or updates provided by suppliers or regulatory agencies is essential to maintaining compliance.

In summary, sourcing SDS involves a systematic approach to locating and obtaining the necessary safety information for chemical substances or products, prioritizing safety, and regulatory compliance throughout the process.

Please write to us at sales@cosmosehs.com

Call us at +1 707 400 0162